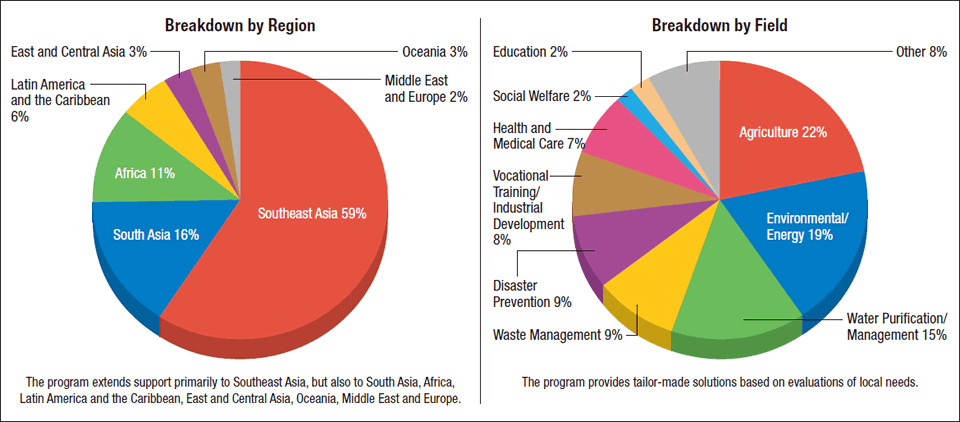

Japan’s Small and Medium Enterprises (SMEs) form the backbone of its high degree of technological development. A large number of these businesses possess expertise and know-how that can help solve issues in developing countries. However, most SMEs find it difficult to conduct market research or procure proper personnel for carrying out overseas projects on their own. In response, the Japan International Cooperation Agency (JICA) introduced a new program for assisting the overseas expansion of SMEs. It enables SMEs to explore their technologies and products’ usability, and serves as a foothold for businesses that contribute to overcoming the obstacles developing countries are faced with. The program has been running for five years and substantial achievements made by Japan’s SMEs are beginning to emerge.

One of these contributions is the work done by Japanese storage tank manufacturer Tamada Industries, based in Ishikawa Prefecture, to provide safer gasoline tanks to Vietnam. Most of the tanks used at gas stations in Vietnam are made of iron and pose a risk of leaking gasoline into the environment when they deteriorate. Double-wall tanks whose outer layer is shielded with fiber-reinforced plastics (FRP) can prevent such eterioration over time and ensure greater safety.

Tamada Industries is the largest manufacturer of double-wall tanks in Japan. It has introduced a unique production method which fuses iron and FRP to increase safety, and specializes in high-precision processing. “The increased use of automobiles has led to a greater demand for gasoline storage tanks in Vietnam, in turn creating a need for safer double-wall tanks. Careful study of local markets and planning of local storage tank production lines supported by JICA greatly facilitated our entry into Vietnam,” explains the President of Tamada Industries’ Vietnamese subsidiary, Yoshihisa Tamada.

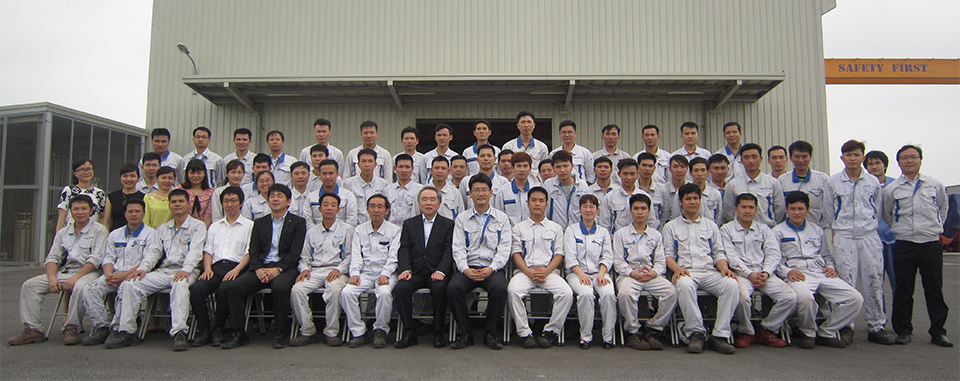

Tamada Industries used JICA’s support to cooperate with Vietnam’s largest supplier of petroleum products, Petrolimex, and undertook efforts to evaluate the effectiveness of double-wall tanks, share its production expertise, and develop maintenance and inspection procedures. Furthermore, locally trained engineers made great contributions by eagerly applying their newly-acquired skills.