With Expo 2025 Osaka, Kansai, Japan set to open this April, one pavilion stands out among the many on display. Featuring the world’s first structure built with a radiative cooling membrane that lowers temperatures without consuming any energy, the pavilion’s groundbreaking material was developed by Japanese startup SPACECOOL INC.

Conceptual image of the Gas Pavilion at Expo 2025 Osaka, Kansai, Japan features an exterior membrane made from SPACECOOL INC.’s radiative cooling material. Inside, visitors can experience XR (cross-reality) content about carbon neutrality. JAPAN GAS ASSOCIATION

Striking triangular structures soar into the sky, their silver membranes reflecting the surrounding landscape to create a shimmering, dynamic exterior that shifts with the weather and time of day. This eye-catching structure is the remarkable Gas Pavilion, one of 13 corporate pavilions at Expo 2025 Osaka, Kansai, Japan, and sponsored by the Japan Gas Association.

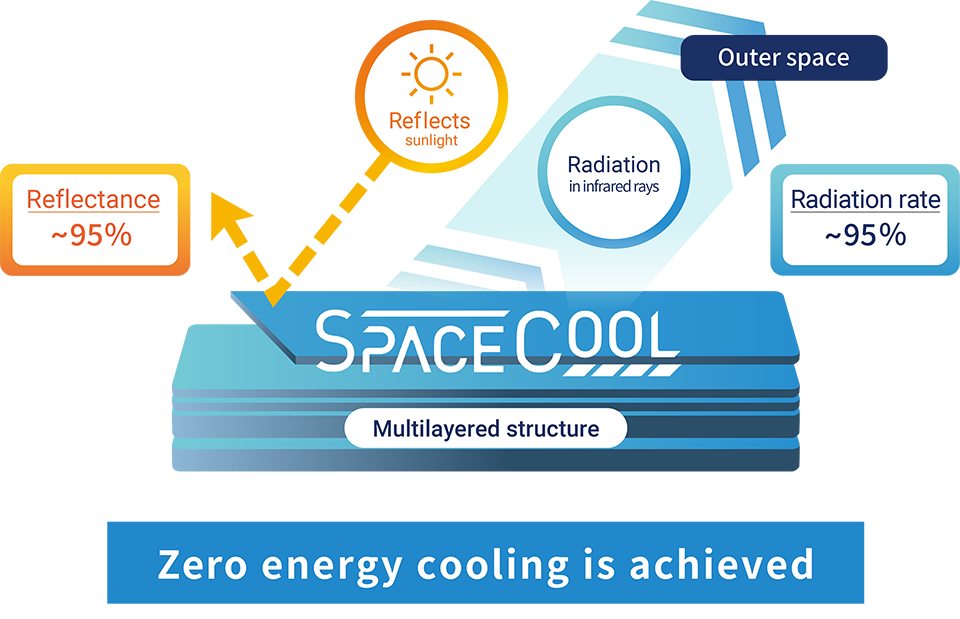

What sets the structure apart is its unique outer membrane. Developed by SPACECOOL INC., a startup from Osaka Gas Co., Ltd.—one of Japan’s leading energy companies—the radiative cooling material not only reflects sunlight to minimize heat absorption but also radiates internal heat into outer space through the atmosphere, effectively cooling objects and spaces without the use of electricity or any other energy source.

Samples of SPACECOOL’s radiative cooling membranes.

Radiative cooling is a natural phenomenon whereby objects cool down by releasing residual heat into the surrounding environment as infrared radiation. An everyday example is the way boiled water gradually cools over time. While the phenomenon itself is perfectly common, SPACECOOL’s proprietary technology enhances this effect. By converting surrounding heat energy into infrared wavelengths that pass through Earth’s atmosphere with minimal absorption—known as the “atmospheric window”—and thus escape into outer space more easily, the company successfully amplified radiative cooling effects and accomplished its commercialization as a multi-purpose membrane material.

SPACECOOL’s membrane reflects sunlight and enhances radiative cooling through proprietary optical engineering technology, releasing surrounding heat as infrared radiation. Its cooling effect is greater than that of standard thermal insulation and shielding materials.

In a demonstration experiment comparing tents made with standard materials and those using SPACECOOL’s membrane, the latter maintained an interior apparent temperature of approximately 10 degrees Celsius lower. CEO of SPACECOOL SUEMITSU Masahiro remarked, “Even the craftsmen who helped construct the pavilion commented on how cool it felt inside.”

While air conditioning will still be used inside the Gas Pavilion during the Expo to help manage Japan’s hot and humid summer months, SPACECOOL’s exterior membrane will reduce cooling demand and overall CO₂ emissions.

The membrane-based design also makes installation and dismantling easy. After the Expo ends in October, the pavilion membrane will be reused, aligning with the 3R principles of Reduce (minimizing building materials), Reuse (recovering the membrane), and Recycle (repurposing other materials). Furthermore, the membrane does not contain any fluoropolymers—commonly found in exterior coatings and known for their high CO₂ emissions during production—demonstrating yet another eco-friendly feature.

Suemitsu explained, “Although several other companies worldwide are researching radiative cooling materials, ours is the only one whose material has cleared stringent tests for tensile strength and resistance to harsh conditions—such as sunlight, wind, and rain—making it viable as a construction material. Our pavilion is the world’s first structure built entirely with radiative cooling material, and we highly encourage visitors to come and take a closer look.”

SUEMITSU Masahiro, CEO of SPACECOOL, holds a doctorate in engineering. He founded SPACECOOL in 2021, building on his research into optical engineering at Osaka Gas.

Beyond architectural applications, SPACECOOL’s membrane is being adapted for various cooling uses. The company’s technology is used as films and magnetic sheets, such as for shipping containers and cubicle switchboards to avoid overheating, as well as easily sewn tarpaulin and canvas materials for sunshades and truck covers, which have already been adopted in diverse environments.

Radiative cooling materials are drawing keen interest in regions such as the Middle East and Southeast Asia, where extreme heat and limited infrastructure for reliable air conditioning remain to be fully developed. In 2024, SPACECOOL conducted a joint demonstration project with two Saudi Arabian governmental agencies. The results showed that using SPACECOOL’s membrane on container houses successfully reduced air conditioning energy consumption by an average 29%—calculated over a 15-year period, the equivalent of roughly 21 tons in reduced CO₂ emissions.

“I feel heat to be a universal sensation and challenge that transcends language,” said Suemitsu. “By expanding the reach of SPACECOOL’s technology globally, we hope to contribute to the fight against climate change.” Expo 2025 will surely provide his company with a valuable opportunity to defy Japan’s summer heat and achieve that mission.

Expo 2025 Osaka, Kansai, Japan

https://www.expo2025.or.jp/en/