Imagine a fabric that transforms everyday clothing into a shield against mosquitoes. In Japan, just such a material is currently under development, designed to reduce the risk of contracting mosquito-borne diseases such as malaria and dengue fever. The countless number of nanoscale pores created in the fibers holds the key to numerous benefits such as enhanced insect repellency and prolonged effectiveness.

Prototypes of clothing, socks, and other items made with Craze-tex infused with insect repellent. FiberCraze aims to apply this technology to not only synthetic fibers, but also organic materials such as cotton. FIBERCRAZE

Above: Prototypes of clothing, socks, and other items made with Craze-tex infused with insect repellent. FiberCraze aims to apply this technology to not only synthetic fibers, but also organic materials such as cotton. FIBERCRAZE

Left: Demonstration tests have confirmed that it effectively repels Aedes aegypti (pictured), a main mosquito vector for malaria and dengue fever. GETTY IMAGES

Demonstration tests have confirmed that it effectively repels Aedes aegypti (pictured), a main mosquito vector for malaria and dengue fever. GETTY IMAGES

It has already been more than five years since the first reports of COVID-19. Although the world appears to have returned to normal, in reality the threat posed by various infectious diseases even now continues to grow. One increasingly pressing issue is mosquito-borne diseases such as malaria and dengue fever. Climate change is expanding mosquito habitats, heightening concerns over wider outbreaks. In 2023, the number of malaria cases worldwide grew from 252 million the previous year to 263 million, with 597,000 mortalities.

While new preventive medicines and insecticides are being developed globally, the most fundamental and effective measure is to prevent mosquito vectors from coming into contact with the body in the first place. If this could be achieved easily by everyone, the situation would improve dramatically. A new technology under development in Japan could be a first step in that direction.

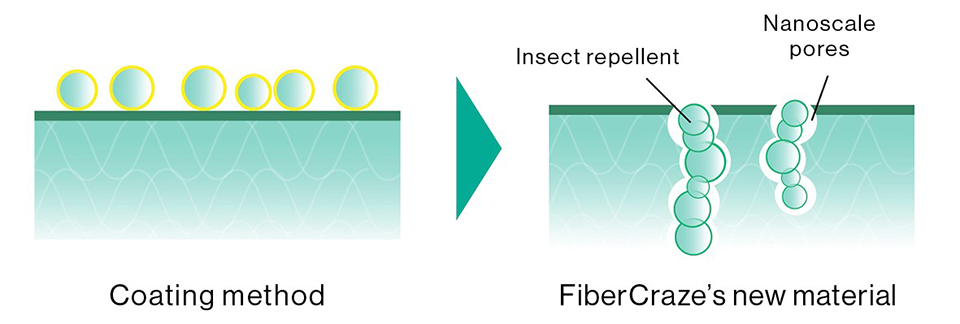

FiberCraze Corporation, a startup from Gifu University, is developing a highly functional fiber material that repels mosquitoes simply by being worn. The foundation of this technology is Craze-tex, a proprietary material made of synthetic fiber perforated with countless microscopic voids less than 100 nanometers in size. These voids, known as “crazes,” can encapsulate various active substances—in this case, insect repellent.

Compared with conventional fabrics that have repellent agents mixed into them or their surfaces coated with repellents, the company’s proprietary material can store approximately four times more active ingredients while allowing precise control over the amount released from its fibers. Infused ingredients do not wash out when laundered, giving them long-lasting effects, and once depleted can be easily replenished.

Unlike traditional surface coating methods (left), FiberCraze’s new material encapsulates insect repellent in countless nanoscale pores within fibers (right). FIBERCRAZE

In experimental trials for insect repellency, untreated material had a mosquito blood-feeding rate exceeding 36%, whereas material applied with mosquito repellent reduced this rate to 5%. “In the future, we aim to enhance the protective effect to cover exposed areas of skin, such as when wearing short-sleeved shirts,” commented CHOSOKABE Shunya, president and representative director of the company.

A joint research project is underway between FiberCraze and the Tropical Infectious Diseases Research & Education Centre (TIDREC, pictured) at Malaysia’s University of Malaya. “Conducting verification tests in local environments, where mosquito species and climate conditions differ from those in Japan, is crucial,” said Chosokabe. FIBERCRAZE

To advance real-world application of this technology in malaria- and dengue-endemic regions, the company launched joint research in 2024 with the Tropical Infectious Diseases Research & Education Centre (TIDREC) at the University of Malaya in Malaysia. Their research includes a demonstration experiment currently underway on Aedes aegypti, a major mosquito vector that is widely found in Southeast Asia and Africa. “The cooperation of TIDREC, a globally renowned institution in infectious disease research, is invaluable. We have already confirmed a mosquito blood-feeding rate that aligns with the results in Japan, and are in the process of verifying the effects of wearing the material in real-life situations,” said Chosokabe.

The technology behind this nanoporous material stems from over 30 years of research into craze by Professor TAKENO Akiyoshi of Gifu University, who is the company’s CTO (chief technology officer). Originally developed for film materials, the craze-creation technique is widely used in privacy screen protector films for smartphones, microbubble generators, and more.

Its adaptation to fibers and textiles with Craze-tex opens doors to various new applications. The prevention of other infectious diseases such as influenza is just one of these. Craze-tex naturally inhibits the penetration of bacteria and viruses, and its fiber nanopores can encapsulate antiviral agents, making it a promising material for masks and other products that could greatly contribute to curbing infection. Chosokabe commented, “We would like to make this technology available beyond brands and national borders, as a material that can help solve social issues simply by being worn.”

CHOSOKABE Shunya, president and representative director of FiberCraze Corporation, holds a shirt made with Craze-tex infused with insect repellent. FIBERCRAZE